Quad Ring Seals

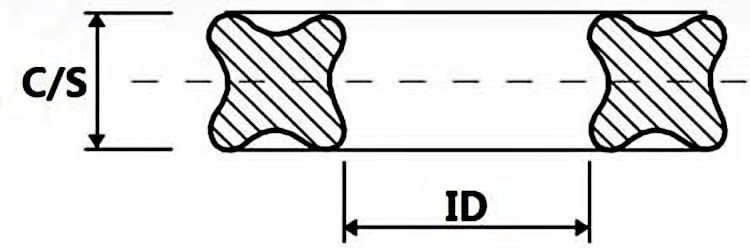

X-ring seal, also known as star sealing ring. It is used to be installed in a groove with special small compression rate to reduce friction, and also be used in the groove with the same specification as O-ring.

X-rings have lower friction and overcome torsion well, then better lubrication; It is able to be a sealing element at lower speeds and suitable for static sealing.

X-ring is a four-lips seal , its shape similar to X and has the following advantages:

1. Compared with the O-ring, the X-ring forms a lubrication cavity between the sealing lips, which has less friction resistance and starting resistance.

2. Because the location of flying edge is in the concave of cross section, so the sealing is very well.

3. Cross-section with Non-circular is able to avoid scrolling during reciprocating motion.

X seal rings has a wide range of applications.

Select the appropriate material according to the temperature, pressure, and medium.

In order to adapt the X-shaped sealing ring as a sealing element to the application situation, we need to consider the mutual constraints between all the working parameters.

The peak temperature, continuous operating temperature, and operating period must be taken into account when determining the application specification.

In the rotating situation, we must also consider about heating.

Quad O-Ring Seal Advantages

X-Ring seals provide four direct points of support for a wide range of applications. The four-lobed design produces a more secure seal to counteract spiral twisting. This allows the use of a narrower groove width than a standard O-Ring groove, but can also be used in a standard X-Ring groove. Quad Ring benefits include:

* Less wear due to low friction, thus providing a longer service life

* Excellent sealing efficiency

* Improved startup with the lubricant reservoir formed between the sealing lips

* Increased stability in dynamic applications

* Enhanced rolling resistance